IoT in logistics:

Why it is a new era

for supply chain

Paul Kirikov

Head of Business Development at Modsen

Moving goods from point A to point B is no longer what modern logistics is about. It's about doing if faster, smarter and safer. Now supply chain is so intelligent it knows where every package is, predicts when a truck might break down, and alerts you the moment something goes wrong – all without a single human touch but via ascending various technologies. So why not find out more about one of these techs – the potential of IoT asset control, which is completely changing the face of logistics?

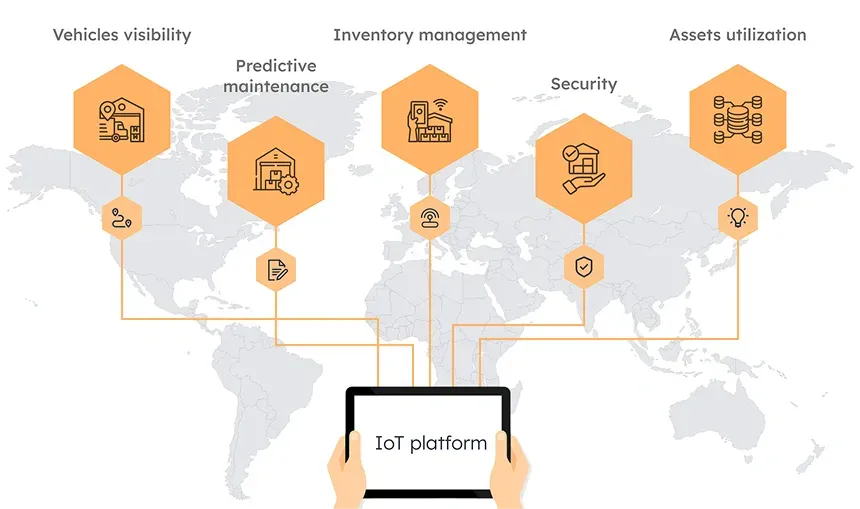

What is IoT in logistics?

At the heart of the IoT in the logistics industry lies a vast network of interconnected devices, from sensors and GPS tracking systems to automated inventory management tools, that operate through the World Wide Web. Specialized sensors are being rapidly deployed in warehouses and facilities, enabling real-time tracking of assets and providing continuous monitoring of their movements – all visualized on a comprehensive digital map. According to statistics, in 2024, the IoT powered logistics market size is estimated at USD 114.75 billion and is projected to reach approximately USD 817.18 billion by 2034, expanding at a CAGR of 21.69% over the forecast period. What’s fueling this surge? Let’s break it down.

360° visibility with IoT asset tracking

Absent IoT integration, businesses risk falling behind in the race for efficiency, as without smart sensors on vehicles, equipment or shipments, they’re blind to critical in-the-moment metrics such as location, temperature or inventory levels.

GPS sensors enable real-time asset tracking using IoT, providing accurate location data and monitoring of planned routes. With geofencing capabilities, they trigger alerts if shipments deviate from designated zones, ensuring security and on-time delivery.

Temperature and humidity sensors in refrigerated trucks monitor conditions within cargo compartments. If the temperature exceeds or falls below the predefined safe range – such as for pharmaceuticals or perishable foods – the system triggers instant alerts to logistics managers.

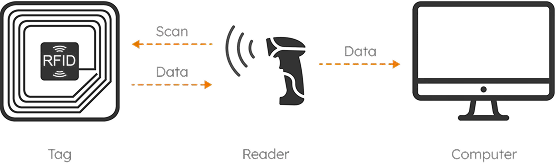

Radio Frequency Identification (RFID) is another component of IoT asset tracking systems. With built-in microchips and antennas, RFID tags enable remote scanning of large inventories and instant stock assessments, even in sealed containers. By attaching a tag to each product, it becomes possible to remotely scan numerous items, conduct instant inventories, and track goods throughout the entire transport path from manufacturer to retailer, ensuring complete transparency.

Predictive maintenance in motion

No real-time insights, costly repairs, delays, and lost productivity – sounds like a bad dream. Without IoT asset monitoring, companies are one breakdown away from these major disruptions. The smart sensor-driven systems pinpoint the potential problems before they become costly breakdowns.

Temperature monitoring is essential to control engine temperature and HVAC systems in vehicles. Sensors trigger alerts if temperatures exceed predefined thresholds, enabling immediate corrective action to prevent engine failure or overheating.

Wear IoT asset tracker measures the wear and tear on key vehicle components like tyres, brakes, belts, and bearings, notifying operators when parts need replacement to keep the vehicle performing.

Humidity control maintains optimal conditions in vehicle cabins and cargo areas for sensitive equipment or driver comfort by activating dehumidifiers or ventilation when necessary.

Pressure sensors detect pressure levels in tyres and hydraulic systems, alerting operators to potential leaks, imbalances, or issues that could affect vehicle performance.

Shock and vibration sensors track excessive vibrations or impacts during operation, helping to identify potential damage to the vehicle’s components or systems.

Usage patterns, analyzed through IoT-enabled asset tracking, provide insights into how vehicles are being used, helping identify areas for performance optimization, efficient route planning, and maintenance scheduling to maximize the lifespan.

Finding it tough to start moving towards new tech?

Leave it to our logistics experts. Contact us now to get the answers you need and put your mind at ease.

Eugene Kalugin

CTO at Modsen

Smarter inventory at your fingertips

IoT logistics solutions extend their benefits beyond vehicles, reforming also warehouse operations through granular visibility into asset quantities and conditions across dispersed locations. These various sensors dramatically curtail human errors or incidents and deliver actionable insights into inventory status 24/7.

Acoustic sensors detect audio vibrations, alerting workers to hazardous environments. By monitoring vibrations, they identify potential risks like machinery malfunctions, maintaining a safe workplace while ensuring compliance with local safety regulations.

Motion and force sensors track IoT asset movements, weight, size, position, and vibration, helping with inventory management by automatically monitoring asset properties.

Chemical sensors analyze the composition of stored fluids to detect dangerous cargo confirm that materials meet the necessary quality standards, minimizing the risk of dangerous chemical reactions or contamination.

Electrical IoT sensors for logistics focus on monitoring the electrical grid within warehouses. By measuring voltage, current, and power, they prevent system failures and reduce the likelihood of power-related accidents.

Environmental sensors monitor all physical conditions within storage areas, tracking factors like temperature, humidity, gas leaks, air pressure, and light to ensure optimal storage logistics IoT solutions.

Image sensors equipped with cameras, infrared, or ultraviolet technology offer enhanced security and monitoring capabilities. These sensors can detect motion or monitor areas for unauthorized access.

Touch sensors detect physical contact with objects, measuring pressure or utilizing the natural conductivity of the human body to register touches, aiding in asset interaction tracking.

IoT in action: Success stories from Modsen

Security at every step

The surge of IoT is fundamentally powered logistics market, shifting from reactive measures to a dynamic, proactive paradigm. Intelligent devices, immediate notifications, and real-time responses converge to create an agile defence system capable of anticipating and neutralizing threats with unparalleled speed and precision.

Motion detectors, equipped with PIR sensors, spot suspicious movements, transmitting data to a central monitoring system and initiating actions such as video recording or alarm activation.

Visual monitoring, including cameras integrated with asset tracking IoT technology, capture images or record videos of intruders and relay this information to the owner via cloud services, thereby enhancing identification processes and supporting investigations.

IoT asset security sensors include intrusion detection and access control systems to protect vehicles from theft or unauthorized access, ensuring the security of the fleet.

Alert systems provide immediate notifications, promptly informing property owners of detected intrusions through messages, phone calls, or communication platforms, thereby facilitating swift responses.

Smart integrations, combining sensors, cameras, alarms, and authentication tools, alongside IoT asset management solutions, create a unified and reliable layer of protection for properties.

Automated systems, which require minimal human intervention, activate in response to potential threats and securely store data locally for subsequent analysis and evidentiary purposes.

Challenges and Solutions

While IoT in transportation and logistics offers considerable advantages, it can sometimes come with certain considerations. For example, integrating data from IoT devices with existing ERP and WMS platforms requires seamless connectivity, and aligning with diverse protocols or legacy systems may necessitate tailored adjustments. Additionally, the initial investment in smart IoT trackers and infrastructure can appear daunting for smaller enterprises, and addressing security concerns might seem like a complex task.

However, our experienced logistics teams is adept at designing flexible, seamless integrations, ensuring businesses can unlock the full potential of IoT solution for logistics without disruption. We take a strategic, incremental approach to implementation, allowing even small-scale businesses to start with high-impact areas and gradually expand. Moreover, we place great emphasis on advanced encryption, secure network protocols, and continuous monitoring, safeguarding sensitive data and devices while maintaining a robust and efficient ecosystem. With our expertise, businesses can confidently navigate these challenges and maximize the benefits of IoT with ease.

Bottom line

Control is everything when it comes to managing logistics, and IoT is redefining what’s possible. With the benefits of IoT in logistics new tech empowers you to optimize every step of your supply chain – from tracking inventory in warehouses to ensuring seamless deliveries. At Modsen, we specialize in bringing these capabilities to life with tailored IoT solutions. Whether it’s streamlining operations or boosting transparency, we’re here to help your business lead the way in modern logistics. Stay tuned!

Get a weekly dose of first-hand tech insights delivered directly to your inbox