Automation and AI for logistics: A strategic way to address labor shortage

Sviatlana Ivanko

Senior Logistics IT Solutions Manager at Modsen

Does your logistics business experience employee deficit? If your answer is a “no”, you are either using magic outside Hogwarts or have already leveraged the power of AI in logistics and supply chain management and opened this article for extra insights.

And for those business owners whose answer is affirmative, we still have some good news: you are most certainly not alone in facing this challenge and the solution to it is much simpler and closer than you think – it's right here in this article.

76% of supply chain and logistics leaders report experiencing labor shortages.

37% of logistics organizations report severe employee deficit.

61% of logistics companies experience transportation disruptions from worker scarcity, and 58% indicate customer service implications.

Transportation and warehousing are the areas suffering the most from manpower shortages.

Struggling to fill in those labor gaps too? Maybe you don’t need to.

Let our logistics IT experts explain why. Leave your email and we’ll reach out to you for a detailed talk, addressing all your questions and bridging any uncertainty gaps concerning logistics process automation.

Paul Kirikov

Head of Business Development

The Modsen way: How to overcome manpower deficit in logistics?

Understaffing in logistics is not an issue that can fix itself over time. The reasons behind it are diverse and you’re not likely to succeed trying to neutralize them with traditional methods like offering a pay raise or an extra day off. Instead, consider taking a strategic tech-driven approach toward logistics automation that will not only bridge your staffing gaps but also unlock a new level of your business potential.

Optimize your workforce with AI

Feasible impact: Overtime costs reduced by up to 25% and delivery timelines met even during peak seasons.

Predictive workforce scheduling

Integrate AI logistics software to analyze workload patterns, employee availability, and demand forecasts to create dynamic schedules that minimize idle time. By forecasting demand spikes and seasonal labor trends, you can manage temporary workers or reassign staff proactively rather than reactively.

Look into the future with ML

Documented impact: Waste and labor costs reduced by up to 20%.

Predictive analytics

Forecasting in logistics and supply chain management is by far the most popular request Modsen logistics team receives from our partners. Machine learning algorithms analyze historical data to predict demand for products and labor, helping businesses adjust their hiring and stocking strategies based on accurate forecasts.

It’s time to automate

Feasible impact: Warehouse dependency on labor reduced by up to 40%.

Zero-touch automation solutions for logistics

It’s no use avoiding the unavoidable – automation in logistics is already defining the future of the industry. With automated warehouse management, you can streamline key tasks like inventory tracking, order picking, and stock replenishment – all without the need for extra workforce. The same goes for repetitive administrative tasks that usually require quite a few employees to complete. Data entry, invoice generation, and compliance checks will no longer be labor-intensive with logistics automation software.

Business transformation stories that speak louder than words

Discover related case studies on AI and automation in logistics and supply chain management.

Let your data rule

Documented impact: Labor productivity improved by up to 20% by identifying bottlenecks through actionable insights.

Customized dashboards and KPI monitoring

Don’t let your business data insights slip through your fingers. Capture it by using custom logistics data analytics software that will create dashboards out of data extracted from all supply chain and warehousing operations. By accessing these insights, your logistics managers will be able to quickly spot inefficiencies and respond in real-time. Analytics tools can also help you track labor productivity, order fulfilment times, and fleet utilization rates to optimize processes even further.

Manage fleet with IoT

Feasible impact: Downtime reduced by up to 30%, ensuring vehicles stay operational with minimal labor involvement.

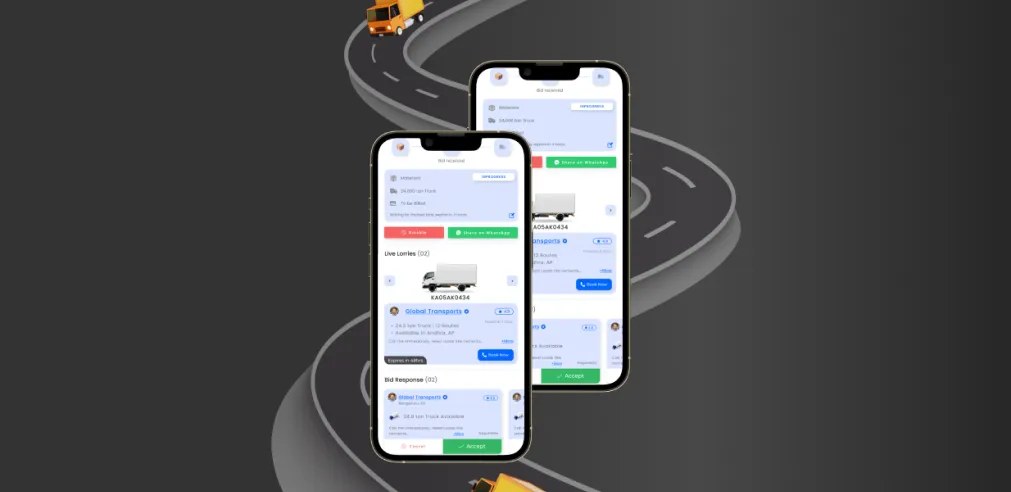

Predictive maintenance, real-time tracking, and route optimization

AI in transportation and logistics allows for all the above by combining IoT sensors and GPS systems with AI algorithms. Tracking vehicle location and condition, optimizing delivery routes, minimizing delays, and rerouting drivers based on live traffic or weather conditions – significant business improvements that do not require extra hands. Besides, IoT devices monitor vehicle health, alerting operators to issues like engine wear or low tire pressure before they lead to costly breakdowns and fleet downtime.

Introduce customer self-servicing

Documented impact: Up to 50% saved on customer support through faster responses.

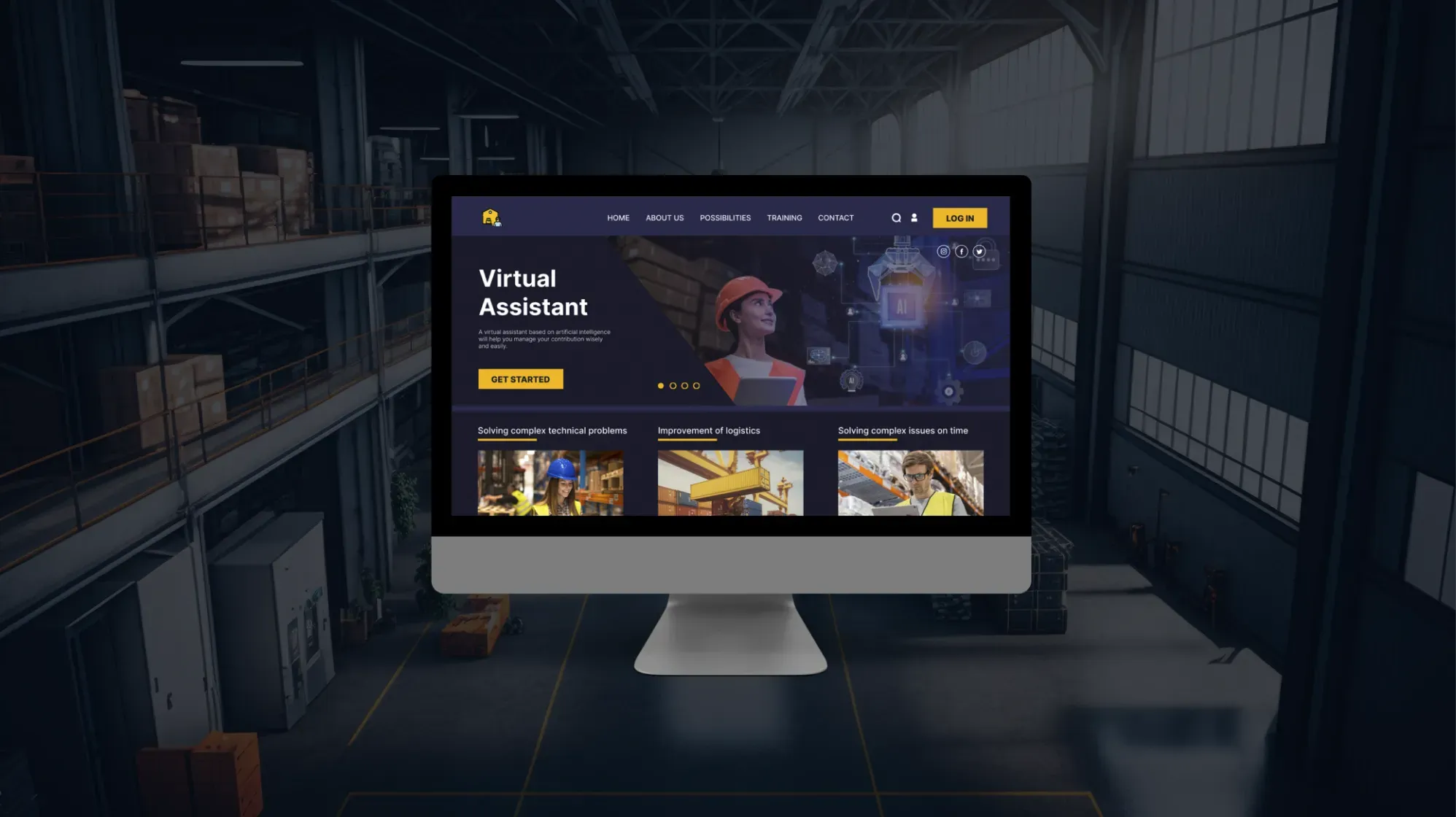

Custom portals, mobile apps, and FAQ chatbots

Why spend thousands on human support having cost-effective logistics automation solutions at hand? Modsen logistics team can help you build intuitive applications where customers can independently track shipments, make inquiries, and reschedule deliveries. Automating customer interactions through self-service portals reduces the workload on support teams, while AI-powered chatbots handle common customer questions, providing instant support with zero human intervention.

Business transformation stories that speak louder than words

Discover our related case studies on AI for Logistics

Don’t look for talent - grow it

Documented impact: Upskilling existing staff reduces recruitment costs by up to 30%.

E-learning systems and gamification training

Studies show that positions for knowledge logistics workers are the hardest to fill. So why struggle? Offer modular training programs to teach existing employees how to work with logistics automation systems and incorporate interactive elements to engage staff during learning, ensuring better retention of new skills.

Test your supply chain with zero risks

Documented impact: Disruptions reduced by up to 50% due to pre-emptive identification of potential bottlenecks.

Digital twins

Logistics businesses now more often than ever turn to digital twin development to simulate, analyze, and optimize logistics performance, reducing costs and enhancing resilience without risking real-life disruptions. You can simulate various scenarios, such as labor shortages and demand spikes, and predict their impact on operations to adjust workflows, inventory, or fleet usage in advance.

Welcome cobots

Documented impact: Warehouse labor needs reduced by up to 30%.

Cooperative robotic systems

Robotic process automation in logistics is gaining traction. Cobots, or cooperative robots, are designed to work alongside human employees, handling repetitive and physically demanding tasks and to enable one employee to manage several cobots, effectively bridging any manpower gaps.

Monetize on transparency

Documented impact: Up to 30% saved on auditing and compliance costs.

Blockchain technology

Blockchain reduces time-consuming and human-error-prone compliance tasks for logistics staff by creating a secure, transparent ledger for tracking goods through the supply chain. You can minimize manual audits and cut paperwork while ensuring that all stakeholders can access verified data.

Labor shortage and logistics: Where did it come from in the first place?

Workforce shortage in the logistics industry is a complex issue that has been triggered by a group of interconnected factors and is not projected to improve unless businesses take a tech-driven approach to logistics process optimization.

Aging workforce and low job appeal

The logistics and transportation sector has a disproportionately older workforce, retiring faster than it can be replaced, leading to a shrinking labor pool. At the same time, logistics jobs are perceived as physically demanding, lacking career progression, and not competitive in terms of pay compared to other industries.

Lack of skilled workers and increased demand for logistics services

The talent gap is a common issue for most industries but in the logistics industry high-skilled employee shortage is significantly more acute. With the rise of online shopping, the shortage is projected to soar even further.

Rising competition for labor and location challenges

Industries like retail and tech are competing for the same pool of workers, as logistics, but they offer higher pay and better working conditions. Namely, many logistics hubs are located in suburban areas, discouraging city-based employees from working in the industry.

Post-pandemic labor dynamics

COVID-19 was the tipping point that led to a mass exodus of workers from the industry due to health risks, layoffs, and economic instability. The global crisis also resulted in a mindset shift of job seekers, who started prioritizing work-life balance, remote options, and flexible schedules - features not commonly associated with logistics roles.

Explore related articles

Harness the power of AI for logistics: A new era of efficiency and service

Could lines of AI code be the turning point that you have been waiting for? Discover how to use the potential of AI in logistics to supercharge your business operations!

5 min read

Unpacking the power of logistics analytics: From raw data to business value

Looking for ways to transform your logistics business with maximum ROI? Explore the opportunities predictive analytics integration has to offer.

4 min read

Real ROI in logistics: Transforming costs into strategic gains

Is digital logistics transformation worth it? Discover how to measure success, maximize ROI, and untap your business true potential with the right strategies and tools.

6 min read

Get a weekly dose of first-hand tech insights delivered directly to your inbox