Optimising car diagnostics and maintenance with AI

45%

lower car maintenance costs

12%

fewer vehicle-related accidents

15%

more accurate vehicle performance info

Challenge

Build a machine learning algorithm that can analyse real-time vehicle data to predict potential maintenance issues.

Solution

Development of an AI-based predictive car maintenance software system to proactively manage the vehicle's state and avoid costly breakdowns.

Client

Our client is a prominent provider of automotive repair and maintenance services in Eastern Europe, serving tens of thousands of customers to keep their vehicles running smoothly. With a mission to empower individuals to confidently navigate the world of car care, they turned to Modsen to amplify their reach to a wider audience and improve customer satisfaction and retention with robust and user-friendly car maintenance software.

Challenge

The automotive industry is rapidly evolving with the integration of advanced technologies. One area ripe for innovation is car diagnostics and maintenance, where traditional methods are often time-consuming and prone to errors. That’s why our client increasingly sought ways to unexpected car failures and overpriced repairs. This challenge focused on developing a cutting-edge software system that utilised AI to predict potential car issues before they become major problems. Our objectives were to:

Implement robust data preprocessing techniques to handle missing data, outliers, and inconsistencies, ensuring data quality for accurate analysis;

Integrate the software with existing car manufacturers' data platforms or third-party APIs to access and leverage existing vehicle data;

Cleanse and standardise data for accuracy;

Develop and train machine learning models to identify patterns and anomalies in-vehicle data, predicting potential issues based on historical data and real-time information;

Provide an intuitive dashboard with actionable insights and personalised recommendations;

Employ robust security protocols to protect sensitive vehicle data and ensure compliance with data privacy regulations.

Estimate the cost of IT consulting services for your project

Leave your email and our experts will provide an accurate estimation of the cost and duration of our IT advisory cooperation.

Team

1

AI Engineer

1

DevOps engineer

2

Full-stack developers

2

UX/UI designer

2

QA testers

1

Project Manager

1

Business analyst

1

Tech lead

Development process

Requirements gathering and processing

To develop an AI-driven predictive car maintenance software system for our partner, we initiated a series of comprehensive discussions to thoroughly understand their specific requirements and challenges. Through close collaboration between our AI specialists, engineers, and the partner's team, we gained the necessary insights into the current state of their maintenance processes, types of vehicle data they collected, existing IT infrastructure, and desired software features and functionalities. These insights helped us formulate a wide-ranging project plan, encompassing essential software functions, data processing algorithms, and integration strategies tailored to meet the client’s unique needs.

Planning

To ensure 100% on-time delivery and meet all project goals, we implemented an all-inclusive development plan based on Agile methodologies and Modsen's established best practices. The planning phase involved the creation of a detailed document outlining resource allocation, project milestones, essential functionalities, and adherence to relevant industry regulations. This cooperative line ensured complete alignment with the client's objectives, guaranteeing the successful fulfilment of the project. Once the first draft was completed and approved, the product development process began.

Team assembly

The process of selecting the project team began with a careful in-house screening process, where all candidates were technically vetted under the supervision of our CTO. This phase verified that the engineers possess required product development experience, a comprehensive understanding of the intricacies of artificial intelligence in the automotive industry, and a keen grasp of the business environment within which our partner operates.

The final team consisted of 1 AI engineer, 1 DevOps engineer, 2 full-stack developers, 2 UX/UI designer, 2 QA testers, 1 project manager, 1 business analyst, 1 tech lead.

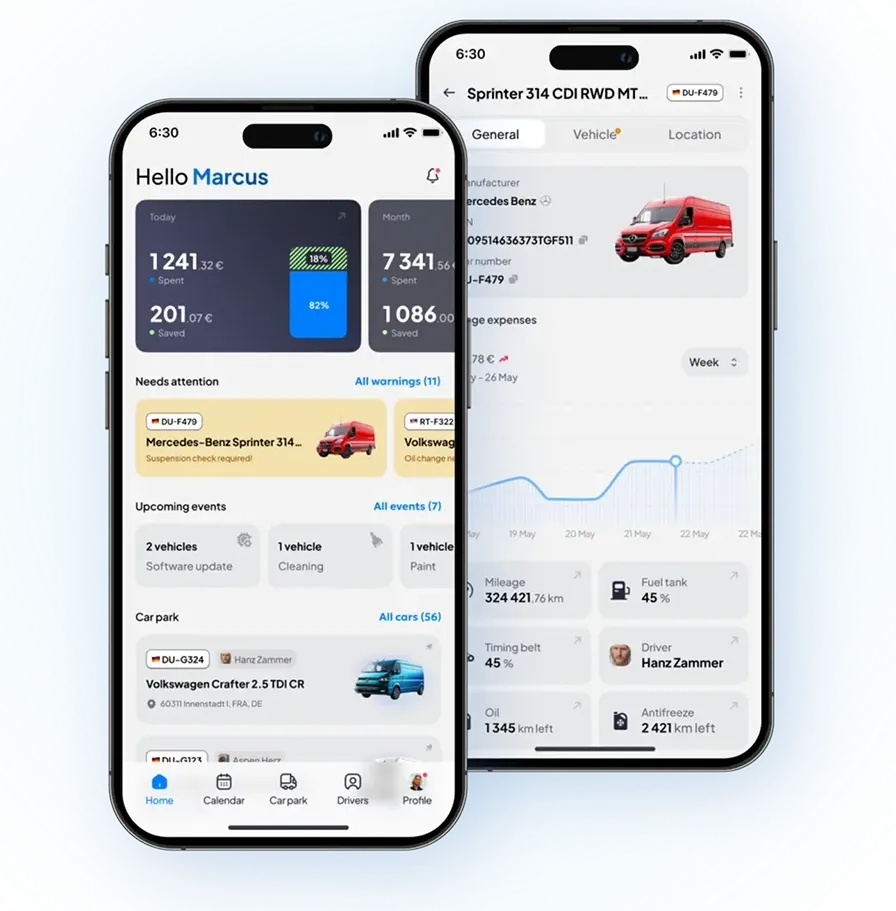

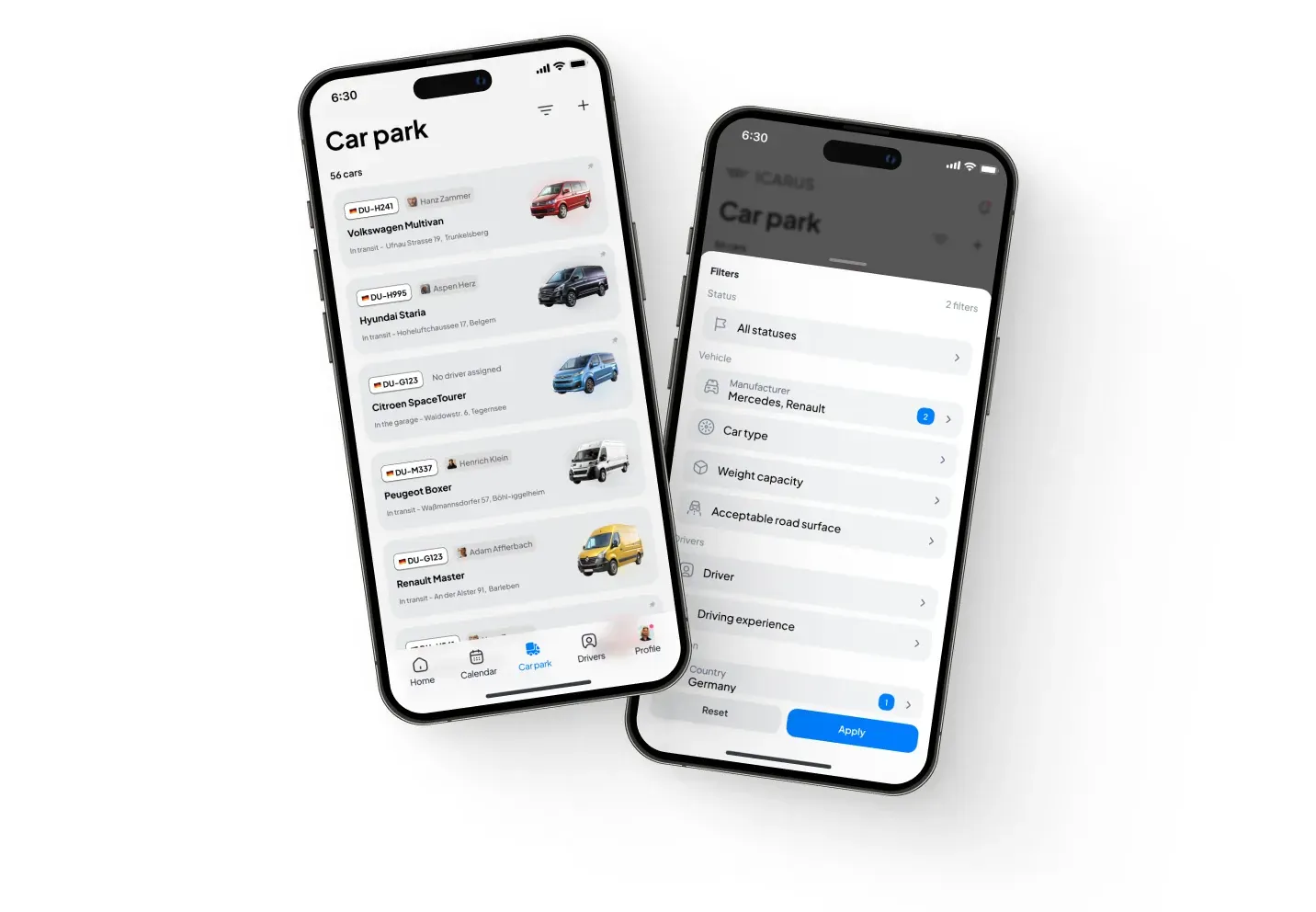

Design

At this stage, Modsen Design Studio professionals created the product interface mock-up, to develop an intuitive and visually appealing design, avoiding complex menus and puzzling navigation, which aligned with the client's branding. Throughout the process, we kept our partner informed of all developments and ensured that the final design would meet their expectations. For this purpose, the UI/UX specialists created more than 30 screens and worked for more than 150 hours to conceptualise an attractive, usable, and responsive AI-based predictive vehicle maintenance software system. The five key stages of the design process included:

- UX research

- UX strategy building

- Wireframing

- Visual design

- Testing

As soon as the final version of the design was complete, the team passed their output to Modsen engineers.

Product building

The development of the AI software was divided into two distinct phases, which were subsequently merged upon the completion of the AI component and its succeeding deployment. The team's approach to this challenge is outlined below:

Software development

After evaluating the available technologies, our engineering team selected Python, Java, TensorFlow, Apache Spark, MongoDB, React, Microsoft Azure, and Docker as the most efficient and suitable for developing a high-quality, robust AI system for car diagnostics and maintenance.

AI module development

To develop the AI component of the software, our team utilised Azure, which provides engineers with the requisite tools and frameworks to rapidly and effectively construct, train and deploy AI models and cognitive search services.

Comprehensive testing

When dealing with AI-powered software, validation becomes even more imperative. To ensure that our client received a smooth, reliable, and precisely functioning car diagnosing software system, QA experts ran a series of manual and automated test scenarios and produced a thorough test report detailing the discrepancies found, which were awaiting resolution by the engineering team.

- Functionality testing

- Accuracy testing

- Usability testing

- Performance testing

- Cross-browser & device compatibility testing

- User acceptance testing

On identification and documentation of the deficiencies, Modsen QA experts promptly forwarded them to the development team for prompt resolution, followed by a re-evaluation of the software fixes.

Integration

As the AI in automotive project neared its completion, our experts prepared extensive technical documentation and a user guide for seamless integration of the software into the client's existing systems.

Servicing and further cooperation

Our commitment to providing comprehensive and ongoing software support extends to all our partners, and this project was no exception. After the-deployment, we kept in touch with our partner to provide support and address any emergent issues. This proactive approach has fostered a long-term partnership, spanning for 24+ months now and maximising value for our client's business.

Result

The final product entirely satisfied all our client’s expectations. Successfully overcoming the project’s challenges, Modsen team created an AI-powered predictive car maintenance system ─ an accessible, affordable, and empowering software, fostering a new era of proactive vehicle care. The AI product, built by a well-versed team of development specialists, has been running for about a year, and below are some of the beneficial changes highlighted by our partner.

45%

Lower car repair costs due to predictive maintenance12%

Reduction of accidents resulted from vehicle malfunctioning15%

More accurate insights into vehicle performance, component reliability and operating patterns